roughing end mill cutter diagram

Roughing End Mills For Aluminum. These lower the shock load during the cutter rotation both enabling a heavier cutting load.

Hpmt Sc Roughing Endmill G6110 Kyocera Unimerco

Often used in rough applications where deep cuts and low horsepower capabilities exist.

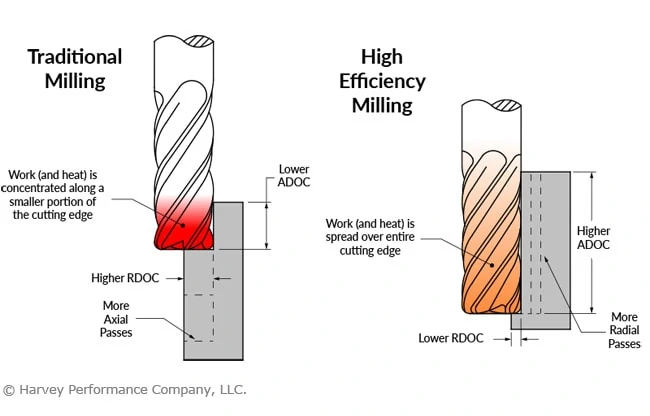

. While traditional roughing is occasionally necessary or optimal it is generally inferior to High Efficiency Milling HEMHEM is a roughing technique that uses a lower Radial Depth of Cut RDOC and a higher Axial Depth of Cut ADOC. Indexable insert milling cutter. These mills have scallops on the outside diameter which causes the metal chips to break into smaller segments.

The flatted shank can be used in a conventional holder. CLICK to browse CORNER ROUNDING FINISHINGROUGHING END MILLS made by world class cutting tool manufacturer Guhring. Roughing End Mills for Aluminium Roughing End Mills for Al-alloy High speed milling over 6000ccmin ded.

Roughing end mills are also famous as rippa cutters. It is a process where rotary cutters remove material which makes it the. Roughing end mills are also sometimes known as rippa or ripper cutters.

Milling Cutters and Tools an Overview. Their extreme hardness means they are brittle so a highly rigid setup such as a CNC machine is necessary to prevent the end mill from. Roughers are one of the hardest tools to get right on a tool cutter grinder as the inside of the flute the top face has to be ground where-as a conventional end mill is sharpened by grinding the outside of the cutter.

3Straight Shank roughing Milling Cutter with 4 Flute. Normally a 20 reduction in effective horsepower is used. The spiral flute end mill compared to a straight flute does a similar function.

Our product line also includes thread taps and dies vernier calipers and digital products. Ball end mills also known as ball nose end mills are used for milling contoured surfaces slotting and pocketing. Carbide Square End Mills.

Roughing end mill Rough-cutters have notches or serrations on the cutting edge which like a mechanical shredder produces shorter easier-to-manage chips. Made of solid carbide these end mills are harder stronger and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard material. One of these automated fabrication methods is CNC milling.

5 Flute Single End w flat 45 Helix Fine Pitch Center Cutting TC Carbide Roughing End Mill. 2Speedy cutting and consume less power. Roughing End Mills - Cobalt and High Speed Steel.

Roughing End Mill Cutters Shop our selection of roughing cutters for use with any End Mill Notcher that requires a 125 shank. Xtratec XT M5004 series. Optimum cutting data and tool life for maximum productivity Maximum process reliability thanks to high stability Perfectly adapted to the machining operation due to different indexable insert.

Regal Cutting Tools manufactures a variety of roughers for a wide range of materials and conditions. Ball nose cutters or ball end mills lower row in image are similar to slot drills but the end of the cutters are hemispherical. CNC rough milling of aluminum can be difficult because the material can stick to the flutes and the chips can pack.

CORNER ROUNDING FINISHINGROUGHING END MILLS. 12 Roughing End Mill. Manufacturer and exporter of rough cutters.

Heavy cuts can be achieved because our roughing end mills have a much higher effective feed per tooth than a conventional end mill. By using roughing end mills we obtain a rough surface finishing. They are ideal for machining 3-dimensional contoured shapes in machining centres for example in moulds and dies.

40 35 63 mm. Todays high performance carbide cutting tools for aluminum have large flutes to yield the maximum metal removal rates possible. End Mills End Mills for Aluminum Roughing.

Roughing End Mills - Carbide Cobalt and HSS. 78 Roughing End Mill. This new catalog represents the results of our continuing commitment to our industry.

Roughing end mills also known as hog mills are used to quickly remove large amounts of material during heavier operations. They are mainly used to rough mill the material off when large amounts of material are removed. Roughing End Mill Cutter Related PostsEnd Mill CutterBall Mill CutterFace Mill CutterHollow Mill CutterSlab Mill CutterThread Mill CutterDovetail CutterFly Cutter.

For over five decades Fastcut has specialized in the manufacture of quality end mills sold nationally through industrial distributors. Design that Virtually Eliminates Flute Packing and Obstruction. Computer numerical control systems offer less need for manpower and higher levels of automation.

1 C-SRA C-MRA C-SRARB 616mm 25mm 655 Õ 5 10 30 50 70 1000 2000 3000. A roughing end mill the type with a wavy corncob outer flute cuts into the part at a higher ratio to the rotation. Five flute Triple Crown carbide fine pitch end mills with a higher helix provides a high shear and lifts chips away from the cutting action.

Cutting method Work material Revolution Feed rate End mill Short 3 flutes Roughing for Al-alloy. These tools are designed specifically for aluminum although they are suitable for a very broad range of materials having up to high tensile strengths. 1Made of High Speed Steel its durable an important fittings for your device.

58 Roughing End Mill. A premium rupture resistant substrate is the foundation to. This type of cutter is used when you have to remove more amount of material from the work piece.

CNC machining is a highly utilised subtractive manufacturing technology. LHY HSS roughing end mill 4 flute. A ball end mill is constructed of a round cutting edge and used in the machining of dies and molds.

They are more beneficial commercially and are used in various industrial applications. Coarse-Pitch Roughing Aluminum CPRA CPRA series milling cutters are coarse-pitch HSSCo8 High-Speed Steel with 8 cobalt 3-flute 37 helix roughing end mills. It is possibler to gash a rougher on a tool cutter grinder or even a pedestal grinder with a hand-formed saucer.

2375 mm - 160 mm. More on this Product Distributors Order Online. The SSDH series achieves superior chip flow and evacuation through the introduction of chip-release flute form technology and a unique inter-flute helical transition all within a patent pending design.

This results in lower cutting pressures at a a given radial depth of cut. This spreads wear evenly across the cutting edge dissipates heat and reduces the chance of tool failure. Founded in 1957 Fastcut Tool lives up to its name with Americas most extensive fast-cutting line of roughing end mills.

Some end mills with fewer flutes are called roughing end.

Speed Feed Recs Melin Tool Company

Solid Carbide Roughing End Mill

End Mills Milling Cutters High Speed Cobalt

Hss Roughing End Mills 6mm 16mm

Programming Tutorials Cnc Programming C C Assembly Python Java Arduino Ebooks Cnc Programming Cnc Programmer Cnc

Pin On Cnc Metalworking And Manufacturing

Milling Cutters Tools Types And Their Purposes With Images

Atc Rough Cutting End Mill 218 2 Indexable Milling Insert Holder Indexable Milling Insert Holder Milling Bar Shenzhen Ussharp Cutting Technology Co Ltd

End Mill An Overview Sciencedirect Topics

Factory Wholesale Corn Milling Cutter Head Bt40 Bmc63 76l Handle Whole Can Insert The Blade Numerical Control Milling Cutter Numerical Control Milling Cutter

8 Ways You Re Killing Your End Mill In The Loupe

Roughing End Mill At Rs 3500 Piece Roughing End Mills Id 18163997088

A Quick Comparison Of Cnc Machine Tools 3erp

End Mill An Overview Sciencedirect Topics

Different Types Of Milling Cutters Used In Machining Process Mechanical Booster

Basic End Mills Technical Information Msc Industrial Supply Co